We design, produce, deliver and start-up complete solutions for surface pretreatment for powder coating

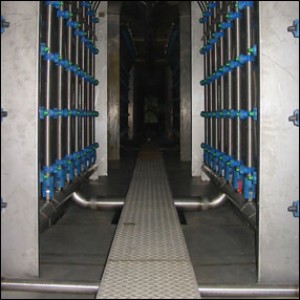

The surface pretreatment tunnels are the perfect solution for small and medium sized work pieces that are pretreated in series.

The surface pretreatment tunnels are assuring the cleaning of the parts, through powder washing, and the forming of a superficial layer of phosphate on the part.

The solutions used by our pretreatment equipments are made by HENKEL SURFACE TECHNOLOGIES.

For delivered utilities we assure services through our specialized personal.

References: ELECTROALFA, AUTOMATICA, ARCTIC.

Surface Pretreatment Tunnel

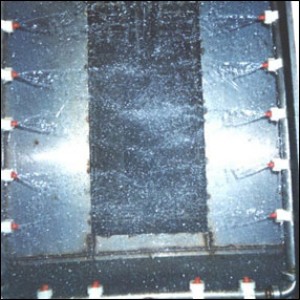

Surface Pretreatment Baths Through Immersion

The surface pretreatment baths are the best option for work pieces that are small or medium sized and are pretreated at wanes or in series.

The surface pretreatment baths assures the cleaning of parts, through immersion, and forms a superficial layer of phosphate on the surface of the part.

The solutions that are used by our pretreatment equipment are made by HENKEL SURFACE TECHNOLOGIES.

For delivered utilities we assure service through our specialized personal.

References: IMSAT, PROMECO, KOBER.

Automatic Dry-Off Ovens

The oven dries off the water remaining from the surface pretreatment.

The heating can be made with methane gas, liquid fuel, GPL or electric.

Depending on the size and constraint production the oven can be made with manual doors or pneumatically functional doors.

For conveying systems the driers are build with pass-by opening, and the openings are equipped with air curtain so the warm air doesn’t get lose.

The driers are equipped with thermostatic system and a counting system for the cycle so the technological cycle works perfectly. In the case of conveying ovens only the thermostatic system is build on, the technological time is given by the conveying speed.

All ovens have safety and protection systems to assure a perfect and save running of the system.

References: ELECTOALFA, ARCTIC, IMSAT, PROMECO, KOBER.

Manual Dry-Off Ovens

The oven dries off the water remaining from the surface pretreatment.

The heating can be made with methane gas, liquid fuel, GPL or electric

Depending for the size and constraint production the oven can be made with manual doors or pneumatically functional doors.

For conveying systems the driers are build with pass-by opening, and the openings are equipped with air curtain so the warm air doesn’t get lose.

The driers are equipped with thermostatic system and a counting system for the cycle so the technological cycle works perfectly. In the case of conveying ovens only the thermostatic system is build on, the technological time is given by the conveying speed.

All ovens have safety and protection systems to assure a perfect and save running of the system.

References: ELECTOALFA, ARCTIC, IMSAT, PROMECO, KOBER.